7 Ways Pantex Protects the Environment

“Greening” information technology

Pantex continues to acquire electronics products that are environmentally sustainable. During FY 2018, approximately 95% of monitors, computers, televisions and other imaging systems purchases were products that met the Electronic Product Environmental Assessment Tool criteria established by the Green Electronics Council. Nearly 100% of all computers and monitors save energy consumption by the use of power management tools.

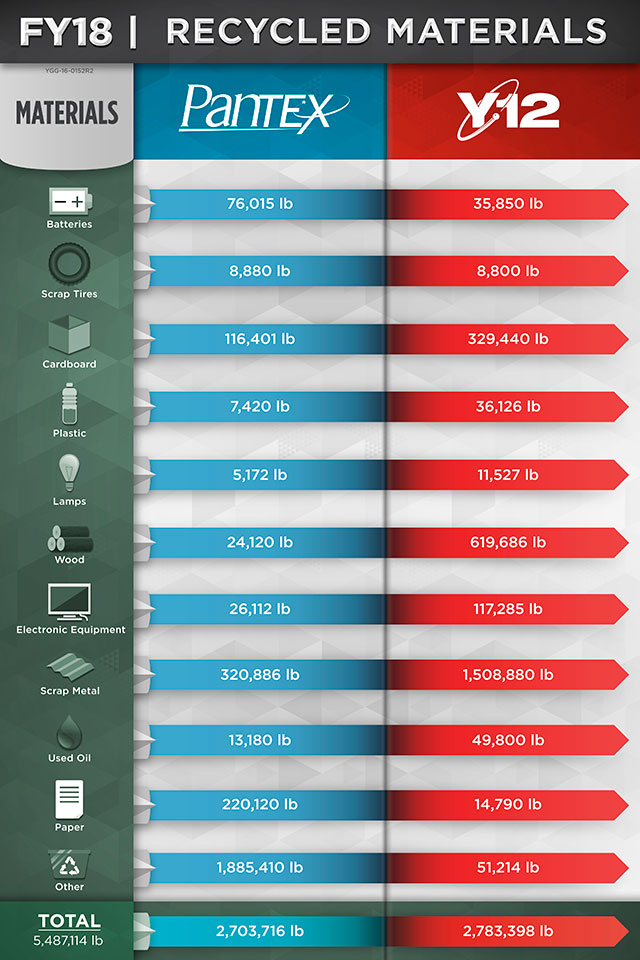

Recycling to prevent waste

During FY 2018 Pantex recycling efforts resulted in the following quantities of waste shipped to various recycling companies:

7,420 lbs.

116,401 lbs.

320,886 lbs.

26,112 lbs.

208,837 lbs.

10,787 lbs.

1,750 lbs.

Following the rules

The Texas Commission on Environmental Quality conducted a waste site inspection of all hazardous and non-hazardous waste locations in accordance with the Annual Resource Conservation and Recovery Act including a records and permit review. This year’s inspection concluded no finding, weaknesses or observations making this the 24th consecutive annual RCRA waste site inspection with no violations.

Minimizing waste

Pantex continues to use digital technology (such as that used with the Radiography X-Ray machine used in the Pantex Occupational Medical Department) to eliminate the generation of silver contaminated film wastes and reduce annual waste generation. More than 1,000,000 metric tons of electronics equipment were disposed of through the use of certified recyclers or transferred or donated to other sites and/or educational institutions through various government programs. Accordingly, 99% of this type of equipment was not disposed of using landfills. In addition, more than 95% of all Pantex printers have duplex printing capabilities to save paper use.

Employing renewable energy

The Plant continues to use renewable energy-powered equipment such as solar-powered aerators in the wastewater lagoons, solar-powered lights at parking lots and solar-generated power to emergency notification towers. However, since the summer of 2014, the operation of the Pantex Renewable Energy Project or “wind farm” has allowed the Pantex site to consistently exceed DOE goals regarding the use of renewable energy and reduce energy-related greenhouse gas emissions.

Reducing energy intensity

Pantex has reduced energy intensity by 20 percent since 2015 primarily through the use of the Pantex Renewable Energy Project or “wind farm.” Energy intensity is the amount of energy used per square foot of plant’s foot print. By 2025, the goal is to reduce energy intensity by 25 percent from the 2015 baseline.

Conserving water resources

Water from a small aquifer beneath the Plant is pumped to the surface and treated to reduce contaminants. The water is then mixed with Pantex Wastewater Treatment Facility wastewater and beneficially reused to irrigate crops in the northeastern portion of Plant property. A similar use of the same water for “center-pivot” irrigations of a portion of the property east of FM-2373 is currently being investigated. In addition, Pantex has established several projects to reduce water consumption by eliminating where possible the use of “once-through” cooling systems.