Interns major in summertime learning

A political science major at UT, Asya H. is gaining knowledge about nuclear safeguards during her internship.

Asya H. comes from a family of engineers.

Her father, Ali, is a civil engineer and assistant director with Tennessee Department of Transportation; her brother, Arda, graduated in the spring with a mechanical engineering degree from the University of Tennessee in Knoxville. So, it seems she is a natural for the CNS Summer Internship Program.

However, Asya didn’t follow in her family’s footsteps and engineered a different path to her internship and arrived a UT political science major.

“My dad is a math whiz,” she said. “He can solve calculus problems in his head. All that math and science goes over my head.”

The rising senior is among 51 CNS interns, who hail from 13 states and 25 colleges. Y‑12 boasts 36 interns, while Pantex hosts 15. With an almost 50 50 split among male and female participants, the majority of interns, 33, are engineering majors, followed by computer science degree seekers.

“The intern program is definitely growing,” said Cristy Landrum, a human resources recruiter at Y‑12. “We had 40 interns last summer. We’re excited to welcome the interns onboard.”

The program began June 7 and offers specialized professional development training, which enhances communication networking, career goal setting, and professionalism. Each intern has a defined work scope and a summer project, which will be showcased at an expo August 10. The program ends August 12.

In summer 2020, the program went virtual because of the COVID‑19 pandemic. This year students have the choice of onsite, remote, and hybrid participation.

The lone political science major (with emphasis on international affairs) in the program, Aysa is going the hybrid route, spending a couple of days on site at Y‑12. Her goal is to become a lawyer and specialize in international nuclear law.

“It’s a very niche kind of field,” she said. “I have a lot to learn. I’m reading lots of legal documents,” which she is doing under the guidance of internship mentor Hannah Hale, a program manager within Global Security and Strategic Partnerships at Y‑12.

This summer, Aysa is primarily working with NNSA’s NA 241, Office of International Nuclear Safeguards. Within the office, she supports NA 241’s International Nuclear Safeguards Engagement Program — whose mission is to work with partners from around the world as they adopt and implement international nuclear safeguards agreements — a pivotal part of the nuclear non nonproliferation regime. For her summer project, she will participate in and support a virtual workshop about import and export reporting requirements under a safeguards agreement with 13 Middle Eastern states.

Kennedy V. is focusing on explosives technology at her third summer stint at Pantex.

A great introduction

As a three‑time intern at Pantex, Kennedy V. has gained a lot from the program.

“It has helped me develop my networking skills and grow as a scientist and engineer,” said the first year West Texas A&M University graduate student. “It’s been great. The hands on experience at West Texas A&M is limited, so coming to work in the Pantex laboratory, I was excited to gain more knowledge using the technology I learned so much about during my undergrad.”

This summer, Kennedy will examine things that go boom, but not really. She is an intern in Explosive Technology in High Explosives and Materials Testing.

“My project will involve the analysis of LM 17 mock composition, using a near infrared spectrometer,” she explained. “The mock material acts as a non‑energetic simulator for inclusion in test assemblies, where actual explosives would be hazardous or unnecessary.”

The composition of the mock explosive should react similarly to its real counterpart without detonation.

The process is only one stage of explosives testing, which has improved over time.

“Once developed, the near infrared technique should only take a couple hours to get composition results,” Kennedy said. “Newer methods have advanced this process to a few days, and there was even a time when it took multiple weeks.”

Kennedy, who also has an undergraduate professional chemistry degree, said “I love explosive technology. It’s a great introduction into the engineering world.”

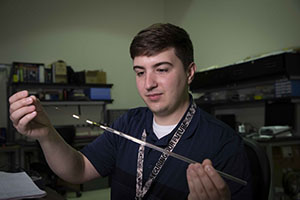

Y‑12 intern Joshua W. holds the sensors used in the ChIMES (Chemical Identification by Magnetoelastic Sensing) Sensor Miniaturization project.

Keeping it current

Intern Joshua W., a senior at Texas Tech University, has returned for his second summer at Y‑12.

“It has been a really great time,” said the electrical engineering major. “The technology is crazy. You learn a lot of stuff in school, but to actually see it play out in a real application is so different.”

Last summer, Joshua’s project was ChIMES (Chemical Identification by Magnetoelastic Sensing) Sensor Miniaturization. The technology differentiates types of and amounts of chemicals present in a system. Chemicals can be sensed through metallic and nonmetallic barriers. When a sensor that is attached to a magnetic wire is exposed to chemicals, the tension applied to the wire changes. This change alters its magnetic properties. For the project, Joshua’s objective was to help transform the tabletop device into a more portable version.

For summer 2021, “It’s a new project, same device,” Joshua said. “There’s still a lot of work to do.” This time he will focus on the device’s sensors.

“I’m going to learn how to fabricate the sensors for target materials,” he explained.

Also, Joshua hopes to install a new circuit board on the device. He has worked on the board for months as a research at Texas Tech.

“I’m integrating the board with a system that’s already built,” he explained. “I’m implementing lab work with a real project. I built this thing and [I am] not sure if it will work on the real device.”

Joshua acknowledges that many hands and minds have touched the ChIMES project.

“There is a long line of interns who have been working on this,” he said. “I’ve just added some of my own flourishes.”