Pantex Blog

7 Ways Pantex Protects the Environment

The Pantex Wind Farm has allowed the site to consistently exceed DOE goals regarding the use of renewable energy and reduce energy-related greenhouse gas emissions.

Pantex and Y-12 are committed to policies and practices that help protect the environment.

Those commitments can be summed up with the acronym P2C2:

- Protect the environment,

- Prevent pollution,

- Comply with applicable legal and other requirements, and

- Continual improvement.

Pantex carries out these promises on a daily basis. Here are seven ways Pantex works to help the environment.

Employing renewable energy

Since the summer of 2014, the Pantex Renewable Energy Project (PREP) has allowed the site to consistently exceed DOE goals for using renewable energy and reducing energy-related greenhouse gas emissions. The wind farm also provides both Pantex and Y-12 with renewable energy credits, which help exceed DOE sustainability goals. PREP was recently featured by DOE as the largest federal wind farm in America. Pantex also continues to use renewable energy-powered equipment such as solar-powered aerators in the wastewater lagoons, solar-powered lights at parking lots, and solar-generated power to emergency notification towers.

Buying Green

Pantex continues the tradition of acquiring products that are environmentally sustainable. During FY 2021, Pantex received the Electronic Product Environmental Assessment Tool (EPEAT) Purchaser Award for purchasing approximately 95% of monitors, computers, telephones, televisions, and other imaging systems that met the EPEAT criteria established by the Green Electronics Council. Nearly 100% of all computers and monitors save energy by using power management tools. Pantex also received the 2021 DOE Office of Sustainable Environmental Stewardship Silver Level Greenbuy Award for purchasing six green priority products in four different categories.

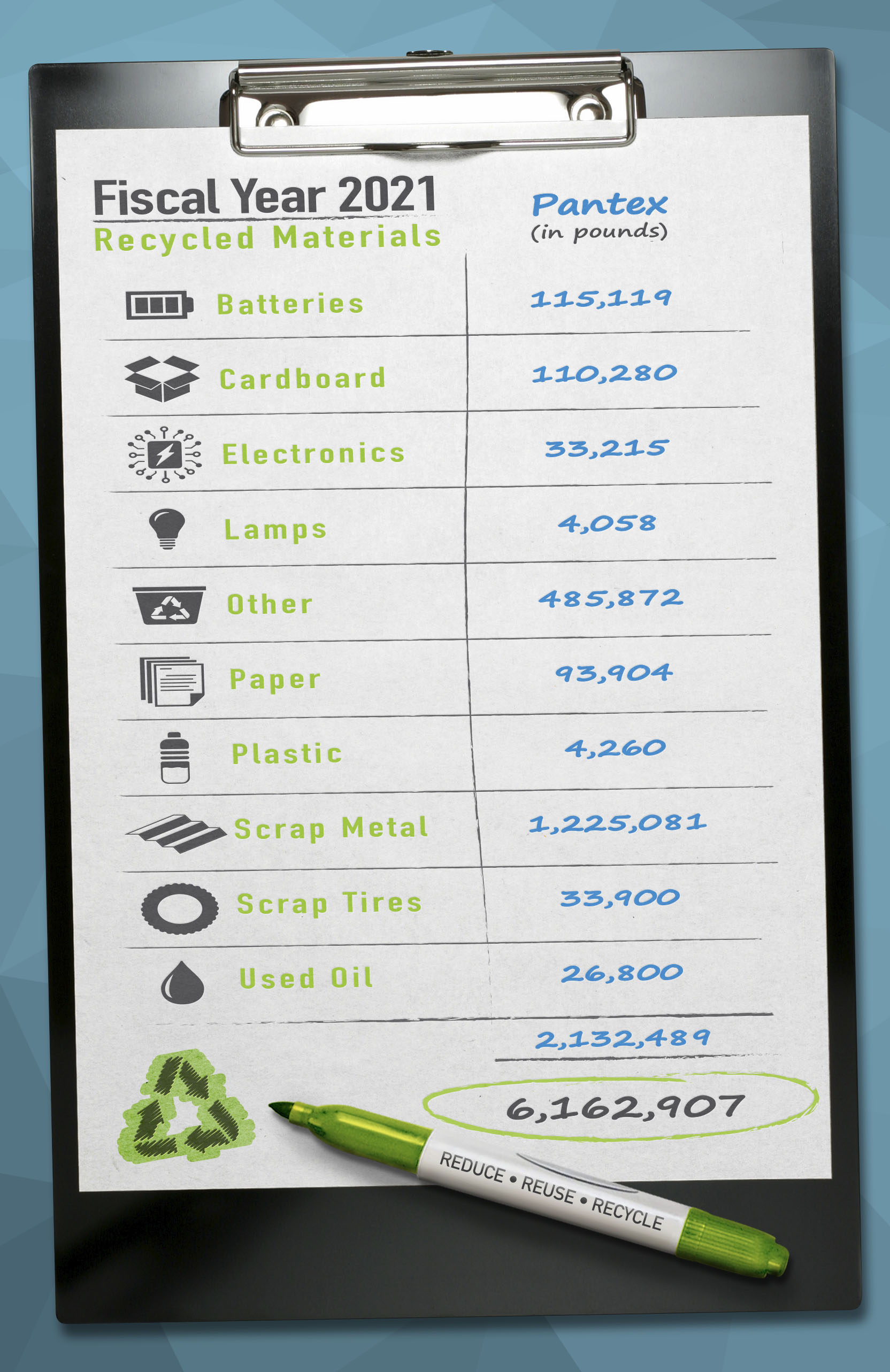

Recycling to prevent waste

During FY 2021, Pantex recycling efforts resulted in a total 2,132,489 pounds in recycled material. The following quantities (in pounds) of waste were shipped to various recycling companies:

- Batteries 115,119

- Cardboard 110,280

- Electronics 33,215

- Lamps 4,058

- Other 485,872

- Paper 93,904

- Plastic 4,260

- Scrap Metal 1,225,081

- Scrap Tires 33,900

- Used Oil 26,800

Reducing energy intensity

Pantex continues to work to reduce energy intensity by 20%, primarily through the use of the Pantex wind farm. Energy intensity is the amount of energy used per square foot of plant’s footprint. By 2025, the goal is to reduce energy intensity at Pantex by 30% from the 2015 baseline. Energy savings in projects such as the heating, ventilation, and air conditioning (HVAC) replacements and security lighting upgrades will further Pantex’s progress in reducing energy consumption.

Conserving water resources

The groundwater remediation program at Pantex focuses on pumping water from the perched aquifer and limiting the amount of recharge back into the perched aquifer. When contaminated water is pumped from the perched aquifer, it is treated to remove contaminants. This treated groundwater is then mixed with treated wastewater from the rest of the plant. Over the last two years, Pantex has renovated a subsurface irrigation system that, under a permit from the State of Texas, allows this treated wastewater to be beneficially reused for crop irrigation. Using the treated wastewater for irrigation increases crop production and reduces the amount of recharge going back into to the perched aquifer. During the crop growing season, between 900,000 and 1 million gallons of treated wastewater may be used in the subsurface irrigation system for the purpose of beneficial reuse. To supplement the subsurface irrigation system, Pantex is constructing a five-pivot irrigation system on Pantex property east of FM 2373. Similar to the subsurface system, the pivots will receive treated water from the plant wastewater facility and the groundwater pump and treat systems to be reused for surface irrigation of crops.

Following the rules

The State of Texas has issued Pantex an environmental compliance rating of “high,” which is the best rating that is offered by the state. The rating is based on Pantex’s compliance with its permits and authorizations and all of the environmental laws and regulations applicable to its operations. In addition, the state has classified the Pantex water supply and distribution system as “superior.” This is also the highest rating offered by the state and is based on performing operations that go beyond those required by regulation.

Reducing waste

Pantex continues to use digital technology, such as the X-ray machine in the Pantex Occupational Medical Department, to eliminate silver-contaminated film wastes and reduce annual radiography waste. Electronics equipment is dispositioned through certified recyclers, transferred, or donated to other sites and/or educational institutions through various government programs. Accordingly, 99% of electronic equipment was kept out of landfills. In addition, more than 95% of all Pantex printers have duplex printing capabilities to save paper use.

Igniting STEM careers in the next generation

Thanks to the many Pantex and Y-12 volunteers who help ignite science, technology, engineering, and mathematics in the next generation.

“When I was in school, I didn’t have …” is a common refrain from generation to generation. Maybe we first heard the phrase from our elders, and now find ourselves repeating it to school-aged children we know. One reason we may say this is because of the many options students have to learn about possible career fields, including the various opportunities science, technology, engineering, and mathematics, or STEM, fields offer. During February, more than 100 Pantexans and Y-12ers once again shared their love for and knowledge of STEM with Panhandle and East Tennessee children during area Science Bowls, Engineers Week, and Introduce a Girl to Engineering events.

“It would not be possible to reach these students without the volunteers who give their time and energy to students,” said Kristin Waldschlager of Y-12 Educational Outreach.

Darla Fish, Pantex’s Educational Outreach lead, agreed. “It is our many volunteers who make the STEM programs successful. Without them, it would be much harder to make an impact on students.”

Volunteers Hannah Bradshaw, Channing Sparks, and Stephanie Steelman of Pantex and Carol Adamson, Cole Bewley, and John Brasher of Y-12 shared why they support STEM events.

Adamson said, “For me, it’s important to share my knowledge with students in order to offer them a different perspective on STEM that I was never afforded as a kid — to let them know that if they’re interested and willing to learn, that’s all it takes.”

“The U.S. as a whole is not focusing on STEM,” Steelman said. “We are not requiring math and science courses as much as we did 20 years ago. By exposing kids to STEM activities at earlier ages, we might pique enough interest for them to start taking math and science classes in middle school and think of STEM professions as a possible career path.”

Several CNS volunteers were fortunate enough to learn about STEM venues while they were students. For Sparks, it was part of her Girl Scout training.

“I participated in a few STEM activities as part of Girl Scouts or at the recommendation of a teacher who had a passion for STEM,” she said. “Many kids have the talent and minds for STEM careers, but they may not be afforded the same opportunities. Sharing my knowledge, journey, and experiences may just be the thing someone needs to hear to push them in the right direction to being a STEM all-star!”

Bewley’s STEM experience in school helped make him who he is today. “I was exposed to STEM activities in middle school, but I became heavily involved when I started high school. At Morristown Hamblen High School East, we had a fantastic program that allowed students to take a variety of STEM classes based off their interests in various topics,” he said. “I was always interested in engineering, so I took all of the basic engineering and fundamentals classes (drafting, robotics, programming, design) that were offered. I believe that my high school STEM experiences played a huge role in allowing me to be successful in college and find a career that I love at Y-12.”

One thing all volunteers love to see when they participate in STEM activities is the children’s reactions when they understand it.

Brasher said, “You don’t know what you don’t know, so by exposing others to your ‘world,’ we foster a more inquisitive mind and show them a new shade of color from the Crayola box. My favorite part of volunteering is seeing kids light up when they see what is possible.”

“When kids start to click with the concepts of engineering, it’s wonderful,” Adamson said. “We had a lot of examples of this at the Industrial Engineering booth at pre-COVID-19 IGTE events. Most girls had no idea what industrial engineering was, but after going through our push/pull process optimization exercise, they were able to see the concepts in action and understand how it could make a difference.”

Bradshaw said, “Everyone knows there are doctors because everyone has been to a doctor. There are countless ways to help people, and letting students know engineering is one of those opportunities is important. It’s rewarding seeing students get interested and start asking questions about things.”

So the next time you see a OneSource announcement asking for volunteers to help with STEM activities, sign up. As Sparks said, “It is important for kids to see themselves in someone who is volunteering because they can relate to them and their experiences, while also knowing that they have the potential to follow the same path or even pave new paths in the STEM world.”

Pantex conducts 30th Regional Science Bowl

Lubbock High School won first place in the Pantex Regional Science Bowl.

On February 5 and 19, Pantex conducted its 30th year of the Pantex Regional Science Bowl and the second year holding the competition completely virtually. It took 64 volunteers each weekend to staff this year’s events. A total of 16 middle school teams and 14 high school teams from across the Texas Panhandle competed for the chance to represent the region at the National Department of Energy Science Bowl in late April.

2022 Pantex Regional

Science Bowl winners:

Middle school

1st place – Hutchinson Middle School

2nd place – Ascension Academy

3rd place – Bonham Middle School Team 1

Best sportsmanship - Lorenzo de Zavala Middle School Team 1

High school

1st place – Lubbock High School Team 1

2nd place – Amarillo High School Team 1

3rd place – Ascension Academy Team 1

Best sportsmanship – Caprock High School Team 1 and Ascension Academy Team 1

The DOE National Science Bowl was created in 1991 as a way to encourage students to excel in mathematics and science and pursue careers in these fields.

“Pantex has run the regional competition since the beginning, and we’ve had so much fun doing it,” said Darla Fish, Pantex Science Bowl regional coordinator. “It is so important to be out in our community and show the students the importance of STEM education.”

The students not only win bragging rights, but also money for their school’s science and mathematics programs. The teams that won the top honors this year were Hutchinson Middle School and Lubbock High School.

To date, more than 325,000 students have participated in the competition, and in its 30-year partnership with Pantex, many thousands of volunteers have stepped forward to ensure a successful competition. Volunteers are what make it possible to run this demanding competition.

For more about Pantex’s 30 years of involvement with the Science Bowl and the importance of our volunteers, see this video.

“The Science Bowl was awesome this year. Our teams had a great experience thanks to Pantex and all your hard work. I really appreciate all of your help,” said Valencia Muniz, science teacher at Canyon Junior High. “The volunteers were amazing and really impressed my kiddos.”

“There have been plenty of changes over the years with Science Bowl, but one thing that never changes is the excitement and spirit of the students and volunteers who step up to the challenge,” Fish said.

Bushland Middle School shows off their Pantex Science Bowl 30th anniversary shirts and bags.

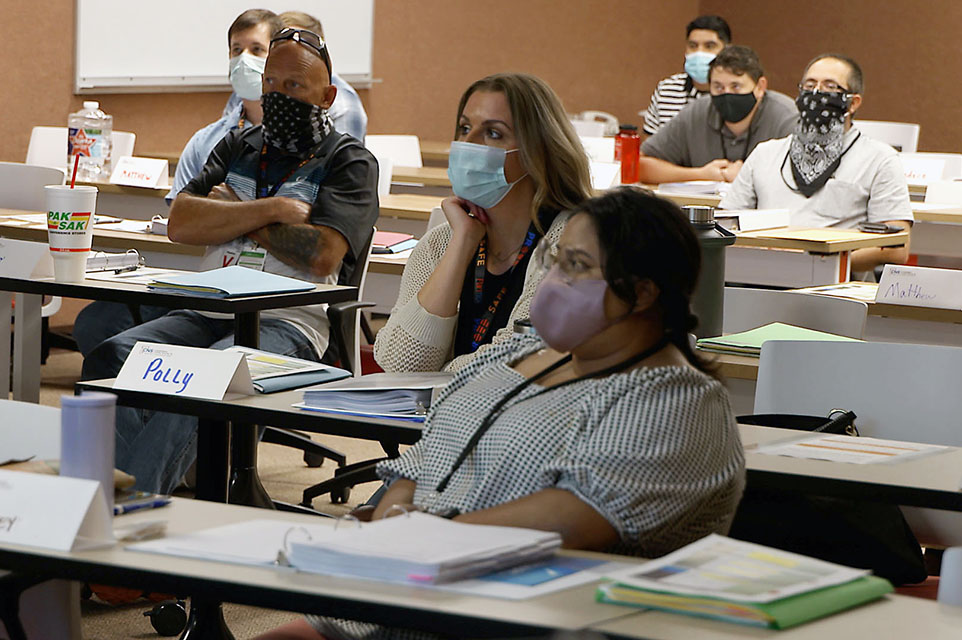

CNS surpasses FY 2021 hiring goal

During a September Pantex onboarding session, new employees learn about the opportunities offered at Pantex and Y-12 and how all employees play a vital role in meeting the mission.

In new employee orientations, incoming Pantexans and Y-12ers are greeted with a simple, but vital message: Every single employee’s contributions are integral to securing the mission of national security. The mission is so important that one of the top priorities of the National Nuclear Security Administration is to continue building the workforce of the future.

Despite the ongoing global pandemic, CNS was able to surpass its hiring goal in FY 2021 due to innovative efforts by human resources, recruitment, hiring managers, and financial analysts. The goal for FY 2021 was to hire 1,277 CNS employees. Between Pantex and Y-12, 1,353 external hires were made.

How has the hiring process evolved?

While requisitions have continued to increase in the last 5 years, the new hiring process at CNS has made a significant difference in recruiting and onboarding top talent this past fiscal year. In 2019, the Human Resources Business Partnerships organization was created, which brought hiring managers, human resources, and financial personnel to the same table to proactively discuss hiring needs for each upcoming fiscal year.

“This new process dramatically changed how we approached hiring and recruitment within CNS,” said Amy Moran, HR strategy and operations director. “Instead of being reactionary, we are having proactive conversations with each organization to determine personnel needs and make sure hiring aligns with funding.”

Groups meet monthly to review metrics to determine whether hiring benchmarks are being met and, if not, what actions need to be taken to meet those benchmarks. The metrics include new hire data, terminations, attrition rates, and internal transfers. The system also takes into account the length of time it takes to recruit new employees, including security clearance time and onboarding training.

“Using the metrics gives us a springboard for conversation and a way to routinely measure if we are meeting our quarterly goals. There have been instances that being able to review this data together has helped us prevent personnel shortages when the unexpected happens,” said Heather Freeman, HR business partnerships director. “We’re able to pivot more quickly and update recruitment strategies in order to make sure our organizations have the resources they need.”

How are we recruiting new employees?

In the past, CNS often relied on in person job fairs, its career listing page, and recruiters reaching out to some potential candidates. Over the last fiscal year, recruitment for the next generation of nuclear security professionals has more aggressively moved to the digital space.

“We have made intense efforts on building our digital brand to recruit top talent for CNS,” said Amanda Hurley, recruitment and placement senior manager. “We’re using proactive recruiters, LinkedIn and Indeed’s recruitment tools, and applicant data tracking databases. Instead of waiting for top hires to find us, we are seeking them out.”

The most visible changes to our recruitment efforts can be found on the Pantex and Y-12 Careers sites, which were created through a partnership with a subcontractor.

How is this affecting CNS organizations?

A group that has seen a significant increase in hiring over the past few years is Y-12 Infrastructure. The organization holds nearly 1,100 employees, with more than 100 hires needed each year. Y-12 Infrastructure has had a dramatic increase in workload along with a heavy retirement wave. Andy Huff, Y-12 Infrastructure deputy manager, shared that the new hiring and recruitment process has made quite a difference for the organization — so much so that they have already met their hiring headcount for FY 2022.

“This new hiring process really comes down to a simple concept: speaking a common language. Human Resources came to the table and started proactively communicating, while being committed to finding a solution to a more efficient process,” Huff said. “This in turn has helped reduce overtime and has increased employee morale within our organization.”

The hiring growth over the last fiscal year was made possible through an enterprise wide effort. Thanks to current Pantexans and Y-12ers, the workforce of the future continues to be built day by day.

“We’re very proud of efforts made over the last year. From Occupational Health personnel fulfilling pre employment physicals at a record pace, to our hiring managers conducting highly efficient interview processes, we have grown our greatest asset: our people,” Moran said. “The mission is essential. We don’t have the luxury to not fulfill these needs, and everyone stepped up to the challenge.”

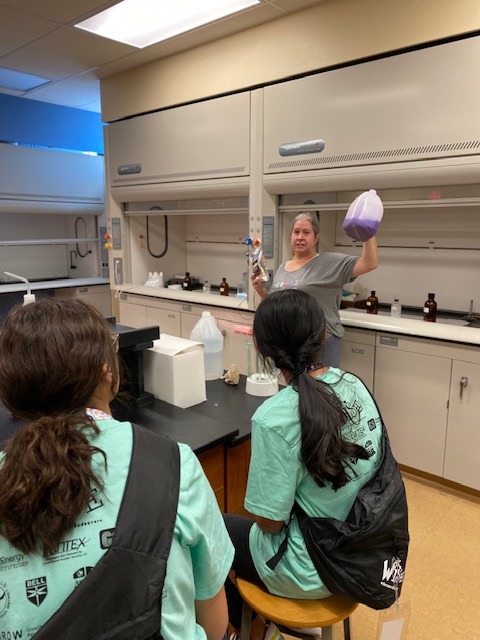

A STEM tradition continues

A more than 30-year tradition continued recently as Amarillo Women in Science Endeavors (WISE) offered sixth-, seventh-, and eighth- grade girls a chance to experience science, technology, engineering, and math (STEM) at a fun, hands-on conference. WISE hosted approximately 300 middle school girls from around the Texas Panhandle for workshops led by women in STEM fields.

Thanks to sponsorships from companies like CNS, attendees received breakfast, lunch, a goodie bag, and participated in three sessions with titles like Surgical Hospital, Bugs are for Girls, Rubber Band Helicopters, and We Be-Lung Together.

Stephanie Steelman, Pantex polymer chemist, led a session called Polymers All Around You to show the girls everyday uses of polymers.

“WISE helps the girls see that science is not hard, and it can be fun in a lot of situations,” said Steelman. “Opening that mental block that they’re not going to be good enough is what we have to overcome. We want to be here to tell all of them that they are good enough to do anything that they put their mind to.”

Nicole Kaufman, Pantex analytical chemistry specialist, agreed that girls having exposure to STEM at a young age shows them that they have the ability to be successful in the fields.

“I see myself in these girls,” said Kaufman. “Sometimes you get that imposter syndrome, so to have someone tell you at a young age that you can do something is really important.”

After taking a year off due to COVID-19 restrictions, the WISE committee was excited to be back with a record number of registrations.

“We had an overwhelmingly positive response to the event this year,” said Allison Roberts, WISE committee member and Pantex Communications specialist. “Our goal is to encourage as many future scientists, engineers, mathematicians, and technology professionals as possible through this annual conference and our scholarship program.”

According to the U.S. Census Bureau, women make up nearly half of the workforce, but only about 27% of STEM workers.

“We are still lacking women in those fields, and women have the capability of thinking in a different way than men,” said Steelman. “We need that diversity in our workforce.”