CNS Infrastructure: Achieving a strong safety record

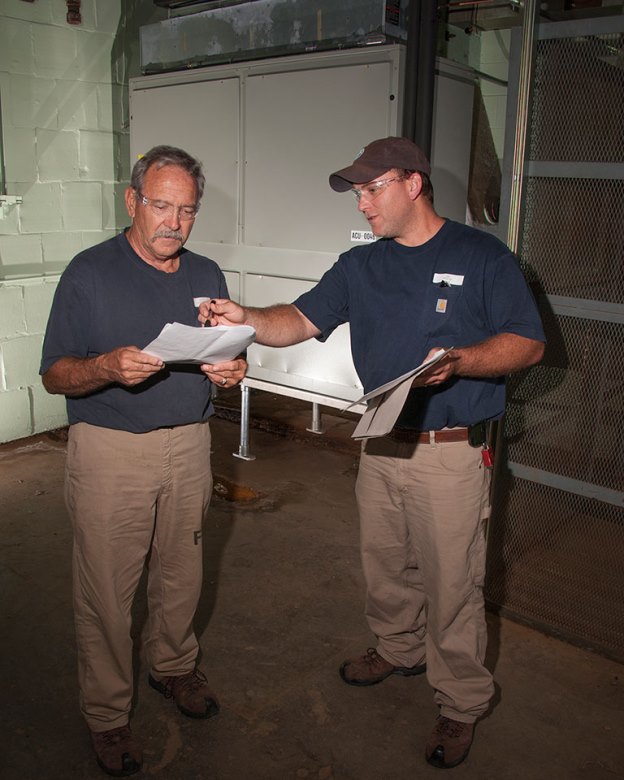

Pantex’s Shaun Ashley (left) and Kirk Spear identify lock out/tag out isolation points on a steam piping system prior to performing work.

Employees in Consolidated Nuclear Security’s Infrastructure organization have worked more than 3.2 million hours since a lost-time injury. For electricians, carpenters, machinists, riggers, welders and other craft personnel at the Pantex Plant and the Y-12 National Security Complex, the “office” is often atop a ladder or in a bucket truck working on high-voltage lines. That’s why working safely is a daily, if not hourly, preoccupation.

“It’s hard to pin down one or two things we’ve done to be successful,” said Scott Underwood, head of Y-12’s Infrastructure group with more than 900 employees who combined have worked more than 2.5 million hours without a lost-time injury. “We’ve leveraged all the people, processes and tools we have in place to make a difference.”

Foremost, explained Underwood, safety is not about a program; it’s about people. “You’ve got to care about your own personal safety and the safety of others. That’s where it starts,” he said. “We’ve also made improvements in some of our processes. When problems do arise, managers, front-line supervisors and craft personnel actively work together to find solutions.”

City of Oak Ridge employees and Y-12 Infrastructure and Environmental and Safety Programs workers gather for a pre-lift safety brief to repair a 24-inch water line on-site at Y-12. Though the recently completed project involved hazardous work, no injuries or negative events occurred.

Finding solutions is part of Steve Passmore’s job. “Every day, people call me and tell me their safety concerns,” said Passmore, one of the Atomic Trades and Labor Council’s safety officers assigned to Y‑12’s Infrastructure group. “We maintain a log, and we work the issues. If it’s a true safety issue, we find the money to get it fixed. However, some issues can be fixed without the need for additional funding. It’s just a matter of getting the right communication to the right people. Then I always get an answer back to those who call.”

Pantex Infrastructure manager Bob Asbury also knows a thing or two about closing the loop on safety suggestions, concerns and solutions. “It is critical that when issues are raised by employees they are welcomed by leadership, but more importantly the loop has to be closed with the employee,” he said. “You owe the employee an answer, and that is best delivered face to face.”

Asbury’s organization of about 375 employees has worked more than 330 days — more than 717,000 hours — without a lost-time injury. He attributes that track record to employee ownership of safety issues and solutions, supervisory engagement and an effective Plan of the Day, or POD. The POD, an electronic document prepared by Maintenance craft workers and management, serves as a daily risk-based review of work activities that then leads into a pre-job briefing.

Pantex’s Maintenance organization implemented the POD three years ago, and the idea has since caught on in other groups at the site. “The response has been truly amazing,” said Shane Feagan, Metal Trades Council safety officer at Pantex. “The POD now reaches people across many organizations at the plant. The most important thing the POD brings to the table is that it ensures we all receive timely and accurate information.”

The Pantex POD description, authored by Feagan, was selected as an Energy Facility Contractor’s Group best practice and is also featured on the Department of Energy’s OPEXSHARE website.

Taken together, the Y-12 and Pantex processes, tools and people undergird the CNS Infrastructure organization’s commitment to creating and maintaining a continuously improving safety culture.

Y-12’s Ron Sharp (left) and Josh Howard (both heating, ventilating, and air-conditioning, or HVAC, mechanics) look over a job package before performing work on an HVAC system. Behind both men is one of the newly installed heat pumps to reduce utility costs and increase reliability.