Pantex Blog

Helping Panhandle children in need through Pantex’s Community Grants

Consolidated Nuclear Security established its Community Investment Fund in 2016 at Pantex. The Pantex Fund is a partnership with the Amarillo Area Foundation, which assists in the distribution of funds, and from the beginning, Pantex created an employee advisory committee to determine distribution of the grants.

One of those recipients is the Amarillo Children’s Home. They have been operating for almost 100 years, focusing on restoring the lives of children in the Texas Panhandle. The majority of their funding, about 70 percent, comes from community support, and the remainder is made up from state contracts.

According to ACH Director of Development, Erica Currie, “Our mission is restore the identity of children, so they can realize their great value and be a blessing to others. We believe this is the birthplace for creating generational change in the Texas Panhandle. Because of community partners like CNS Pantex, ACH has been restoring those lives. You make our work possible, and we are so grateful.”

This year, the Community Investment Fund gave $10,000 to ACH and the entire amount was earmarked to its “Feed the Tummy, Fill the Soul” program. “Around 30,000 Texas children are currently in foster care, and securing resources for each child is challenging,” said Currie.

“Most foster children have been exposed to conditions that undermine their chances for healthy development, and their needs are great, including the need for nourishment. While this is not surprising, the way ACH uses a simple meal to help transform lives is unique.”

ACH's house parents use mealtime to bring everyone together to teach valuable life skills, like nutrition, team work, planning, cooking, table setting, and etiquette. The house parents and children work together to plan, cook, and serve nutritious meals, and everyone has a role to play. Around the dinner table, families talk about their day, and each child is engaged on a personal level. As a child begins to feel loved and accepted, doors open for them to excel in other areas like school.

“While feeding children is simple, ACH uses it as an opportunity to also feed a child’s soul, to love on them, and to remind them that they have not been forgotten. This is paramount in breaking the cycle of abuse that is prevalent in today’s foster care system,” said Currie. To Pantex employees, she said, “Thank you for partnering with us as we care for our children, allow them to see their great value, and teach them to be a blessing to others.”

The Pantex committee prioritizes grant applications from organizations located and operating in the 12 contiguous counties surrounding Pantex, with the emphasis on: Basic Needs, Child and Family Development, Education, Community Development, Financial Literacy, and Health and Wellness. In four years, including the latest round of grants, CNS has given more than $860,000 to area non-profit organizations through the Amarillo Area Foundation.

I am mission success: Ryan Warren

Take 5 minutes and learn more about CNS’s Ryan Warren, Metal Trades Council Culture Advocate. All views and opinions are the employee’s own and do not necessarily reflect those of CNS,/abbr>.

Ryan Warren worked as an electrician at Pantex for six and a half years until recently being named the new Metal Trades Council (MTC) Culture Advocate. During his time at Pantex, he has also served as MTC Shop Steward and Recording Secretary and on the International Brotherhood of Electrical Workers (IBEW) Local Union 602.

Some of his duties now include reporting significant events and trends identified within the plant to both MTC officers and senior management.

“I want to foster open, honest, and helpful communication in all directions between management, union, and otherwise across organizational boundaries, and more,” Warren said.

Another part of his job is to develop ideas to implement improvements; train new employees on Pantex Safety Culture; and manage, promote, and advocate for positive change in the workplace.

“Some of my goals are to recognize problems and contribute to developing solutions and to promote a respectful, safety conscious, and ever-improving work environment,” he said.

Warren said that while he loved his work as an electrician, he’s excited for his first real desk job in 15 years and to be able to help in this new capacity.

“I’ve always promoted brotherhood through solidarity and teamwork,” he said. “I left a good job for a better one, and I want to help keep it that way, for myself and others.”

Why are you mission success?

I am mission success because I work to build trust by honoring my commitments, not making promises I can’t keep, and staying consistent. As a tradesman, the only thing I have to sell is my integrity. I always strive to do the right thing, regardless of who’s watching. Although I have faltered many times along the way, I do my best to keep these values regardless of the job I’m assigned. Respect is built on guiding, learning, teaching, and leading by example.

Are you doing what you envisioned as a young adult?

Apparently, being a rock star isn’t as easy as Bachman Turner Overdrive would have one believe. Fishing is way easier. I was working as a telemarketer selling ketchup popsicles when a buddy of mine told me he got a job as an electrician. He said he got to bend pipe, spit and cuss, pull wire, and dig ditches all day. That sounded better than what I was doing, so I applied at the IBEW Local Union 602, got in the apprenticeship program, joined the union, and four years later became a journeyman. It was the best career move I have ever made for myself and my family. I jumped on the Pantex train a few years after that.

As an employee, what do you want to be remembered for?

I hope to be remembered as level-headed, disciplined and thoughtful; unafraid to speak my mind, yet open-minded. I want everyone to know that I care about the well-being of all of my coworkers, union and all.

What’s your top bucket list item and why?

I hope to one day see the Parthenon in Greece and the Colosseum in Rome. I want to visit Yokosuka, Japan, where my mom was born, and San Diego, where she was raised. I also want to take my boys to see the Christian heavy-metal band Impending Doom. All equally important to me.

What’s your favorite outside-of-work activity and why?

I’ve been married to my wife for 18 years and have two boys. My favorite thing in the world is doing anything with my lovely family: playing kickball, music, movies, cooking, board games, church, reading comics, wrestling on the trampoline, eating Asian cuisine, watching grass grow, getting beat at Plants vs Zombies; I love it all. Although lock-down and quarantine have been tough for everyone, I’ve been remarkably blessed by the most amazing family, and I cherish all the time we’ve gotten to spend together over the last year. They are my entire world.

Amanda Clark finds construction field rewarding

To celebrate Women in Construction week, we are highlighting Amanda Clark who oversees projects for the National Nuclear Security Administration Office of Enterprise Project Management (NA-APM-20) at Pantex.

Clark is currently the Federal Project Director for High Explosive Science and Engineering (HESE) Facility and for the High Explosive Synthesis, Formulation & Production (HESFP) Facility, and also manages the Material Staging Facility project for NNSA. She holds a Bachelor of Science degree in Business Management and has been working in project and construction management since 1998.

“I started as a document control clerk and junior construction inspector for an Architectural/Engineering firm, discovered how challenging and rewarding the work was, and quickly progressed to senior inspector and then project manager,” she said.

She first came to Pantex in 2004 as a self-employed subcontractor through the U.S. Army Corps of Engineers to support NNSA on Facilities & Infrastructure Recapitalization Program (FIRP) project execution. She has been a federal employee since 2009.

When asked what the most fulfilling part of her career is, Clark compared it to parenthood, which is a journey of joy, heartache, and pride that many can relate to.

“Getting to help my teams achieve their career goals and watching their professional growth has to be the closest thing to the journey of parenthood that I’ve ever experienced in my career in project management,” she said. “Of course, helping to build structures that will still be around and operating long after I have retired is also pretty cool!”

She went on to say that all the things she has helped to build in NNSA contribute in such a direct and meaningful way to national security missions is just a bonus.

“It is a pretty incredible feeling to say, ’I knew him or her when….’ as my team members progress on in their careers, or to be able to point to a building and tell my kids ’I helped build that.’ Nothing like it in the world,” she said.

Amanda’s mother, a registered nurse, is the person who has inspired her most.

“My mother is one of the sweetest, kindest, and most giving people I’ve ever known,” she said. “But she also always stands up for what she believes and defends her position tenaciously. I grew up hearing her talk to my dad about balancing speaking up to doctors without seeming to challenge their authority in order to ensure her patients’ voices were heard; while I’m sure she didn’t think I was listening, it definitely taught me some important lessons about the art of negotiation.”

She says her mom showed her the value of speaking up in a respectful way, and inspired her to encourage her teams to always contribute by proving she will listen to their advice and address their concerns.

“My mom is also the epitome of ’tough but fair’ and I’ve always tried to emulate that quality, either as a supervisor or as a project manager,” she said.

She said it is important to encourage and educate young women about job fulfillment from skilled trades because we spend more hours at work than pursuing any other single activity, so it should really be rewarding and enjoyable, and something you look forward to.

“Not everyone was built to work in the confines of an office, but I think there has been a reluctance by women to jump into fieldwork due to some weird perception that you have to choose between femininity and following your heart to do hands-on work,” she said.

Clarks said she’s always been what you might consider a bit of a tomboy, but has never viewed her job as limiting.

“I’m just as comfortable dressing up to go to the opera as I am putting on work boots and a hard hat to kick the dirt and talk to work crews so I can understand any challenges and help our buildings/projects go more smoothly and be more efficient,” she said. “I would love it if every young woman could experience that, such that all the perceived barriers would just disappear for future generations.”

Her advice for other women who may be interested in pursuing a career in construction is that it is a rewarding field, and there are no longer the same barriers that existed when she first started working on projects 20 years ago.

“No person in this country should feel that this field isn’t open to them,” she said. “If you are fulfilled by working with your hands, building things, being part of a working team, and finding creative ways to solve problems, then working on a project site as a tradesperson or in engineering or project management can be very rewarding. If you do what you love, work becomes a joy.”

Clark is always excited to see other women on the jobsite, as she’s still outnumbered by her male counterparts.

“Girls today seem so much braver and bolder to me than I felt growing up, but I know it can still be a little daunting to go into a position or trade where you know you have to ‘prove’ yourself,” she said. “I think it is important to recognize that men entering the skilled trades experience the same learning curve, so women should not let fear deter them. It does get easier, and I’m now at the point where the quickest way to get me to jump a hurdle is to tell me why I can’t!”

Pantex Community Investment Fund benefits local foster children

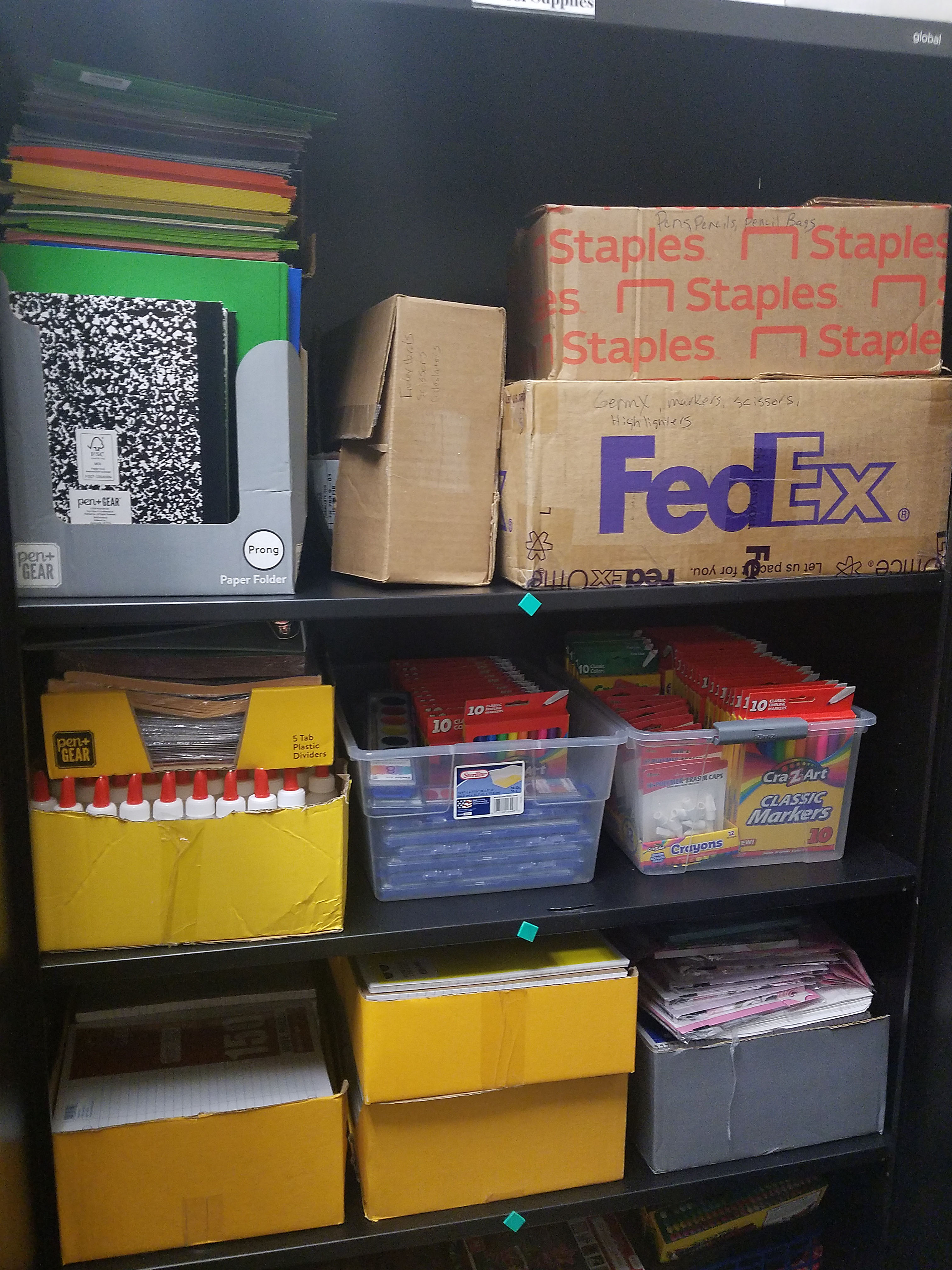

Amarillo Foster In Texas received a backpack and school supplies from the Pantex grant.

Three siblings between the ages of four and seven were living in a trailer with no running water. The oldest sibling served as the primary caretaker for his two younger siblings. After joining a stable home through foster care, they are able to recover from the trauma and thrive.

Through the $7,500 grant given to Upbring from the Pantex Community Investment Fund, these siblings, and other children served by Amarillo Foster In Texas, received backpacks and school supplies to help them gain confidence and succeed.

Upbring is a leading Texas-based, faith-inspired nonprofit organization working to break the cycle of child abuse by empowering children, families, and communities. They work to benefit families with life-changing programs—including foster care, adoption, education, children’s centers, and community services.

“Pantex’s support of children in foster care and their families is making an impact when our community needs it the most,” said Mary Kathrine Matalon, with Upbring. “The gift from Pantex has made an impact in Amarillo that will be felt for generations to come,” Matalon said. “We thank them for joining with Upbring to create a world where every child is loved, protected, and cherished.”

In addition to backpack and school supplies, foster families received swaddling blankets, baby bed sheets, and other necessities so they could provide a loving home for infants and toddlers in foster care, and two kinship families received funding to cover home inspection costs and a gap in subsidized day care.

A member of the Pantex Community Investment Fund Employee Advisory Committee, Brian Jones, is grateful for the partnerships that allow Pantex to impact the lives of those in the Panhandle.

“As a former foster parent myself, I know how important community support is. This grant, and the joy that it provides, has impacts on our community for years to come,” he said.

Amarillo Foster In Texas hosted a Back to School party where foster families enjoyed two hours of bowling, pizza, and soft drinks. The event closed with the distribution of school supplies and backpacks.

Pantex’s grant will also be used to make dreams come true this Christmas by fulfilling the wishes of foster children. A celebration for foster families will also be held if it is safe to do so.

Consolidated Nuclear Security established the Pantex Community Investment Fund and has been helping local organizations since its inception in 2016. The Pantex Fund is a partnership with the Amarillo Area Foundation, which assists in the distribution of funds. In 2020, 16 nonprofits in the Texas Panhandle received grants equaling over $121,000 from the fund during a virtual ceremony.

From the beginning, Pantex created an employee advisory committee to determine distribution of the grants that target charities and non‑profit organizations that offer assistance with basic needs, children, youth, families, community development, education, financial literacy, as well as health and wellness.

Amarillo Foster In Texas received a backpack and school supplies from the Pantex grant."

Amarillo Foster In Texas hosted a Back to School party where foster families enjoyed two hours of bowling, pizza, and soft drinks."

Safety employs ingenuity to help protect Pantex personnel

The Pantex Plastics Shop designed and produced modular plastic shields to deploy across the site.

In their continued effort to find solutions to ensure employee safety during the pandemic, Pantex Safety and Industrial Hygiene sought out cooperation across the site to employ new plastic shielding at various locations on site.

“We recognized that breakrooms and lunchrooms presented a challenge when employees are eating and drinking as the masks have to be removed,” said Shane Feagan of Pantex S&IH. “While organizations have worked throughout the pandemic to stagger breaks and lunches with socially distanced tables and chairs, the plastic barriers are an added physical layer of protection.”

After identifying the need, S&IH reached out to the onsite Plastics Shop to help with the design of modular Lexan shield that could be configured in multiples or standalone units to fit each area’s need. Procurement also stepped up to quickly procure the needed Lexan. The Plastics Shop used the water jet system to increase production to 40 shields per day. To date, over 160 sheets of Lexan were ordered to meet demand. The shop is currently sending them to organizations all across the site.

“I am extremely proud of how the Plastics Shop helped us recognize this challenge and continue to work tirelessly to fulfill the orders to ensure their coworkers are safe,” Feagan said. “By making these on site, we not only saved significant costs versus ordering the shields, but we are able to quickly manufacture them and put them in use.”

The shielding has been deployed to many organizations already, including Weapons Training, Medical, Counterintelligence, Security, and Quality. More orders will be shipped out to all of the south end breakrooms and both cafeterias. There are currently over 400 requests for shielding being worked.

“It is our hope that the shielding keeps employees safe so that we can fulfill our important mission and send them home safe to their families each day,” Feagan said. “These are challenging times, but I am grateful that employees continue to do everything we can to ensure we are able to continue to work safely. It reinforces that Pantex employees are truly the best and I am extremely thankful that I get to be a part of the Pantex family.”

Lexan plastic shields have been added to breakrooms for added protection when eating without a face covering.