Pantex Blog

Pantex hosts NUWAIX 2019 exercise

Pantexans and supporting staff from Y-12 practiced taking appropriate protective actions, activating the Emergency Response Organization, and coordinating with other agencies during the 2019 Nuclear Weapons Accident/Incident Exercise April 24-29. Hosted at Pantex, this large-scale, full-participation exercise involved numerous local, state, and federal agencies including Carson County, Amarillo Police Department, FBI, Office of Secure Transport, Texas Department of State Health Services, Environmental Protection Agency and others.

While NUWAIX is held annually, hosting responsibilities rotate between DOJ, DOD and DOE, with DOE/NNSA leading every five years. The purpose of the exercise was to strengthen the ability of all involved to respond to the national, regional, and local effects of a scenario involving a nuclear weapon-related incident. The last DOE-led NUWAIX was in Grand Junction, Colorado, in 2014.

Daniel Gleaves with Pantex Emergency Services said, “The visibility provided by this exercise allows us to demonstrate our ability to respond to an emergency, builds confidence from DOE in the Pantex plant and our response capabilities.”

This year’s simulated scenario was incident-based (meaning an intentional act) and gave the participating agencies a chance to put their skills, procedures, postures, communications and coordination to the test. While the plant took protective actions, the Emergency Response Organization members from Pantex and supporting staff from Y-12 played their part on the scene, at the Emergency Operations Center, and the Joint Information Center. The plant was prepared for and received the deploying members of the Nuclear Emergency Support Team’s Accident Response Group to address the technical aspects of the scenario.

“At Pantex, you have a great emergency infrastructure here and you folks know that you are dealing with one of the most sensitive activities in the national nuclear enterprise,” said Jay Tilden, Associate Administrator and Deputy Undersecretary for Counterterrorism and Counter Proliferation. “There’s a certain level of safety here and procedural control that is exceptional. So, the idea that we would even have an accident is pretty low.”

“The NNSA must always be prepared for an emergency of any kind,” Tilden said. “Going through an exercise like NUWAIX 2019 is critical because it’s a complicated scenario requiring a lot of moving parts. And if we don’t exercise it, we may not be ready.”

There were approximately a thousand participants in the exercise, including hundreds of controllers and evaluators. Carson County Judge Daniel Looten, who participated in the exercise, said over the years he has come to know the Pantex emergency personnel through monthly meetings and mutual aid events.

“That trust and bond exists. I’m very secure to know that my citizens in Carson County are being very well protected and the people out here at Pantex do all they can to keep us safe,” Judge Looten said.

Throughout the exercise and tours, visitors were impressed with Pantex’s emergency preparedness. The objective of the event was met in that it gave the teams a chance to determine best practices and possible improvements.

For more images of NUWAIX 2019, see the Pantex Facebook site.

NNSA authorizes full-scale operations at the High Explosives Pressing Facility at Pantex Plant in Texas

WASHINGTON – The Department of Energy’s National Nuclear Security Administration (DOE/NNSA) has authorized full-scale operations at the Pantex Plant’s High Explosives Pressing Facility (HEPF) in Amarillo, Texas, following extensive readiness reviews.

The Pantex Plant is the Nation’s primary facility for the final assembly, dismantlement, and maintenance of nuclear weapons. Replacement of high explosives in weapons is an important part of NNSA’s mission to maintain and extend the life of the U.S. nuclear stockpile.

“NNSA is modernizing the Nuclear Security Enterprise to face 21st century threats,” said Lisa E. Gordon-Hagerty, DOE Under Secretary for Nuclear Security and NNSA Administrator. “Our dedicated stewards of the nuclear deterrent at the Pantex Plant deserve this modern, safe infrastructure to accomplish our team’s national security missions.”

HEPF replaces existing machining and pressing facilities that are over 50 years old and consolidates operations to reduce the movement of high explosives within the plant, increasing employee safety and minimizing impact to other plant operations.

NNSA broke ground on the 45,000 square-foot, state-of-the-art facility in 2011. Managed by the U.S. Army Corps of Engineers using a firm fixed price contract, construction was completed in 2017.

7 Ways Pantex Protects the Environment

“Greening” information technology

Pantex continues to acquire electronics products that are environmentally sustainable. During FY 2018, approximately 95% of monitors, computers, televisions and other imaging systems purchases were products that met the Electronic Product Environmental Assessment Tool criteria established by the Green Electronics Council. Nearly 100% of all computers and monitors save energy consumption by the use of power management tools.

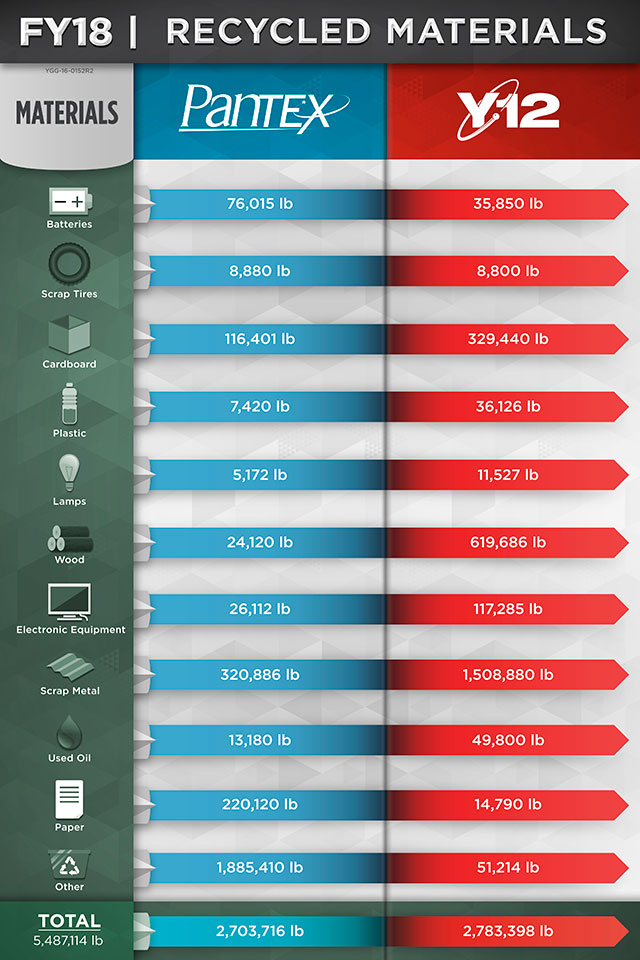

Recycling to prevent waste

During FY 2018 Pantex recycling efforts resulted in the following quantities of waste shipped to various recycling companies:

7,420 lbs.

116,401 lbs.

320,886 lbs.

26,112 lbs.

208,837 lbs.

10,787 lbs.

1,750 lbs.

Following the rules

The Texas Commission on Environmental Quality conducted a waste site inspection of all hazardous and non-hazardous waste locations in accordance with the Annual Resource Conservation and Recovery Act including a records and permit review. This year’s inspection concluded no finding, weaknesses or observations making this the 24th consecutive annual RCRA waste site inspection with no violations.

Minimizing waste

Pantex continues to use digital technology (such as that used with the Radiography X-Ray machine used in the Pantex Occupational Medical Department) to eliminate the generation of silver contaminated film wastes and reduce annual waste generation. More than 1,000,000 metric tons of electronics equipment were disposed of through the use of certified recyclers or transferred or donated to other sites and/or educational institutions through various government programs. Accordingly, 99% of this type of equipment was not disposed of using landfills. In addition, more than 95% of all Pantex printers have duplex printing capabilities to save paper use.

Employing renewable energy

The Plant continues to use renewable energy-powered equipment such as solar-powered aerators in the wastewater lagoons, solar-powered lights at parking lots and solar-generated power to emergency notification towers. However, since the summer of 2014, the operation of the Pantex Renewable Energy Project or “wind farm” has allowed the Pantex site to consistently exceed DOE goals regarding the use of renewable energy and reduce energy-related greenhouse gas emissions.

Reducing energy intensity

Pantex has reduced energy intensity by 20 percent since 2015 primarily through the use of the Pantex Renewable Energy Project or “wind farm.” Energy intensity is the amount of energy used per square foot of plant’s foot print. By 2025, the goal is to reduce energy intensity by 25 percent from the 2015 baseline.

Conserving water resources

Water from a small aquifer beneath the Plant is pumped to the surface and treated to reduce contaminants. The water is then mixed with Pantex Wastewater Treatment Facility wastewater and beneficially reused to irrigate crops in the northeastern portion of Plant property. A similar use of the same water for “center-pivot” irrigations of a portion of the property east of FM-2373 is currently being investigated. In addition, Pantex has established several projects to reduce water consumption by eliminating where possible the use of “once-through” cooling systems.

StormReady designation helps ensure all Pantexans remain safe in severe weather

The National Weather Service (NWS) recently recertified the Pantex Plant (Pantex) as a StormReady community.

StormReady is a program that aims to mitigate the loss of life and property related to severe weather, and there are multiple requirements necessary to receive a StormReady designation.

“It requires that Pantex plan for and train our personnel on a number of severe weather-related events, mostly focused toward severe thunderstorms and tornados,” Pantex Emergency Preparedness Specialist Brian Veach said. “We also had to conduct training and drills as well as provide procedures and briefings to the site personnel.”

In addition, Pantex was required to demonstrate multiple methods to receive severe weather watches/warnings and had to show that there were procedures in place to communicate required protective actions to the plant population.

This designation is usually only sought by a city or county as very few companies have the resources and dedication to undertake the process. Because safety is a priority for Pantex, this designation demonstrates that commitment.

“Our drills and exercise program go above and beyond what the Department of Energy requires and really stress severe weather,” Veach said. “It’s not just the large site-wide drills or exercises, but we also run a number of facility-based shelter for severe weather drills.”

In addition to drills, Pantex also offers classes instructed by the NWS on severe weather storm spotting to all Emergency Management Department (EMD), Fire Department, Fire Department Support Team, and building/floor wardens.

Personnel from EMD also visited the local NWS office in Amarillo to increase cooperation and understanding of what information and services could be provided to Pantex.

“We participate in their Weather Ready Nation Ambassador program as well, which means we receive emails from the NWS with seasonal weather information and share that with our personnel on the site,” Veach said. “This helps increase the overall weather knowledge of the entire plant population.”

Part of the process to recertify included personnel attending a severe storm spotting class that trains personnel to recognize severe storm characteristics and report them accurately to the NWS in Amarillo.

Veach said management is committed to keeping personnel safe not only at work, but also at home.

“The information the company provides in training for severe weather is just as applicable at home as it is at work,” he said. “I can carry the skills and knowledge I’ve gained from work to my home, and that helps make my family safer.”

He continued by saying that people are Pantex’s #1 asset, and keeping everyone safe is vitally important to the site mission.

“Knowing how to remain safe when, not if, severe weather affects the plant means we have the skilled, trained, and dedicated personnel to continue our critical national security mission,” Veach said.

Personnel from Emergency Services and the Building Warden Program assisted Emergency Management in accomplishing this recertification.

“The building wardens are an essential part to this,” Veach said. “Emergency Management, and the larger Emergency Services Organization, cannot be everywhere when severe weather arrives. Having the highly skilled wardens available that can extend the reach of Emergency Management helps ensure everyone on the site is taken care of and remains safe.”

Veach also said the Plant Shift Superintendents are the first line of protection in severe weather.

“Those unseen heroes make regular contact with the National Weather Service to keep us all safe,” Veach said. “They play a major role in the site receiving severe weather notifications and directing the appropriate protective actions.”

Pantex was originally designated as StormReady in October 2015, and this was the site’s first full renewal in the program. Pantex was required to go through the entire recertification process, including a visit from the local StormReady board.

“The renewal process requires us to re-demonstrate this commitment to them at three-year intervals, with a spot check halfway through,” Veach said. “StormReady is not a once-and-done thing but a culture that exists on the site thanks to the hard work of a number of personnel including Emergency Services, Emergency Management, and all of our wardens.”

Pantex Fire Department a good neighbor to surrounding communities

The Pantex Fire Department is ready to serve Pantexans 24/7/365. But did you also know they also respond to requests for mutual aid in the communities surrounding Pantex?

That’s right. The Pantex Fire Department (PXFD) averages 52 calls per year from agencies in the surrounding communities for not only assistance with wild land fires, structure fires, and motor vehicle accidents, but also with medical assistance with the Pantex ambulance.

“The fire department averages 26 responses for structure fires, wild land fires or motor vehicle accidents and 26 responses for medical assistance with our ambulance per year,” Pantex Fire Captain Sean Fox said. “We can and have responded to rescues in Palo Duro Canyon with our rescue team.”

According to Pantex Fire Chief Mike Brock, the PXFD responds to one or two requests for mutual aid per week, but they are currently seeing an increase in the number of requests due to the declining number of volunteers available in the surrounding communities.

“Other than Amarillo, the fire departments in the communities around the plant are all staffed by volunteers, and many of them struggle to have enough responders, especially during the day,” Brock said.

A recent example of mutual aid was a call for a house fire in Panhandle, Texas, on Saturday, February 23. The Panhandle Fire Department had only two volunteers respond to the call and PXFD responded to a request for mutual aid to assist in the structure fire.

Bonnie and Justin Whitehead, who are both Pantexans and volunteer with the Panhandle Fire Department, responded to the call for the Panhandle FD.

“My husband and I were the only ones that showed up for our fire department and were a little anxious about that situation,” Bonnie Whitehead said. “When the guys form the Pantex FD showed up, they immediately jumped into action. All the guys fought tirelessly to try and save the home. The Pantex FD is always willing to aid the Panhandle FD in any situation and it is greatly appreciated.”

The Battalion Chief on shift each day makes the determination of when the PXFD will respond to a mutual aid request, but the plant always remains the department’s primary responsibility.

“We respond as long as we can still support plant operations when responding off plant site,” Captain Fox said.

In addition to full-time firefighters, the PXFD utilizes a Fire Department Support Team (FDST) made up of volunteers from across the plant. These volunteers are not trained for interior firefighting, but provide support for most other aspects of the fire department operations on an emergency scene.

“They may be called up to assist in a mutual aid wild fire response if the need arose and they were able to respond,” Fox said. “There is not a requirement that they have to respond, but when notified they respond when they are available and on plant site.”

The Fire Department’s mission is “Caring for People” and according to Chief Brock that includes not only Pantexans but also the local communities.

Captain Fox echoes those thoughts and says PXFD’s willingness to assist neighbors gives them an opportunity to learn from one another.

“I feel that it is our responsibility as community neighbors to assist when we are needed,” Fox said. “We can bring resources (equipment, trained personnel, and apparatus) that they may not have access to without our support. By meeting with and working with them they also become more comfortable to assist us on site should the need ever arise.”

The PXFD is staffed 24/7/365 with firefighters working 24 hours shifts.

“Just like Security, our department is staffed and ready to respond at any time,” Chief Brock said. In addition to responding the emergencies on plant site and assisting with mutual aid requests in the surrounding communities, the PXFD also supports other functions within the plant.

“The fire department accomplishes monthly fire extinguisher inspections, building inspections, hot work permits,” Captain Fox said. “We also instruct new hire training, self-contained breathing apparatus (SCBA), and fire extinguisher training for plant employees as needed.”