Pantex Blog

CNS Enterprise Fire Department Team wins Sportsmanship Award at HAZMAT Challenge

A combined CNS Enterprise Fire Department Team represented Pantex and Y-12 at the 2019 Hazardous Material (HAZMAT) Challenge held at Los Alamos National Laboratory (LANL) recently.

The combined team did an outstanding job representing both sites and were voted by the other teams and operators in the competition as winners of the Sportsmanship Award. This award recognizes a team that embodies the values of working as a team, working with other teams, and being willing to step up wherever a need arises.

The combined team did an outstanding job representing both sites and were voted by the other teams and operators in the competition as winners of the Sportsmanship Award. This award recognizes a team that embodies the values of working as a team, working with other teams, and being willing to step up wherever a need arises.

“The CNS Enterprise FD Team did an excellent job. It was rewarding to see how they came together the first day operating as one team in the events,” Doug Trout, CNS Senior Director, Enterprise Emergency Services said. “The planning beforehand and collaboration by the team was evident in all of the events. They have ideas for training to take back and are looking forward to next year. This was an excellent event.”

The HAZMAT Challenge has been hosted by the Emergency Management Division of LANL for the past 22 years, and HAZMAT teams network with one another, practice technical skills, and learn new HAZMAT techniques under realistic conditions in a safe environment.

During the Challenge, vehicles, trucks, tankers, and rail cars are used in some of the props to mimic real-life hazardous material situations. Past Challenge scenarios have included drug laboratory or chemical hazard identification, manipulation of complex valve configurations to stop leaks, confined space rescue, compressed gas leaks, a leaking rail car dome, pressurized drum opening, stinger operation responding to damaged tanker trailer, and damming/diking exercise from an overturned tanker.

Lyle Cary, Vice President of Safeguards, Security, and Emergency Services added, “The training value and relationships built during these events strengthens capability across the Nuclear Security Enterprise, and because of the number of teams from federal, state, and municipal departments, it strengthens the Nation”.

Lyle Cary, Vice President of Safeguards, Security, and Emergency Services added, “The training value and relationships built during these events strengthens capability across the Nuclear Security Enterprise, and because of the number of teams from federal, state, and municipal departments, it strengthens the Nation”.

Representing Pantex were Firefighters John Sappington, Daniel Sholder, and Cody Steever, and Fire Captains Mark Campbell and Chad Zarbock.

Representing Y-12 were Firefighters Chris Altman, Scot Rose, and Craig Shaver, and Fire Captains Jeremy Maiden and Jim Arnold.

Pantex Fire Department members train newly formed Y-12 Honor Guard

Members of the Pantex Honor Guard visited Y-12 in June to train their fellow firefighters.

“We received approval to form an honor guard, and we decided who better to train us than our fellow coworkers,” Y-12 Assistant Fire Chief Mari-Kaye Monday said. “Pantex’s Honor Guard was established in 2011.”

Three Pantex members conducted a week of training with the 10 members of the newly formed Y-12 Fire Department Honor Guard.

“We wanted to ensure we were ready to serve as a color guard or perform a variety of events, such as opening ceremonies, parades, and funeral services for fallen fire and emergency services members,” she said.

Monday said their team has worked for years to establish an honor guard within the Y-12 Fire Department. “It is the mission of the fire service honor guard to exemplify honor, respect, and dignity while embracing fire service tradition. We’re continuing the pursuit of excellence by establishing the honor guard, and the Y-12 Fire Department is striving to exhibit pride, professionalism, and teamwork to represent CNS.”

Pantexan demonstrates Phases of Matter at Canyon Library

Pantexan Bruce Phebus with HE Materials and Testing recently presented a demonstration on the Phases of Matter to children at the Canyon Library.

Bruce talked with the children about how gasses expand and cool, the components of air, and how clouds form.

He performed demonstrations such as balloons in the vacuum chamber, the Franklin cup, and touchable clouds for the children whose average age was around 5 years old.

“I think science demos are important because science shouldn’t be abstract. It should be something people and kids realize is a real job and it explains the world,” Bruce said. “I think science without seeing scientists in person and demos is like watching water polo from the Sahara. Any given kid can’t even imagine the pool let alone someone playing in it.”

He said doing these types of demos makes science relevant for children, and explains the world that children touch and see every day.

“It isn’t just ‘facts’ in a book that are untestable and unverifiable on their own, things they just need to accept,” Bruce said. “The key tenant of science is trust but verify! Learn it all for yourself!”

Pantexan recognized with EFCOG award

Kimbel Leffew with Pantex Contractor Assurance is a member of the Human Performance Improvement Working Group team that was awarded the HPI Team Award by the Energy Facilities Contractor Operating Group at its annual meeting in Washington, D.C.

Chris Clark, Leffew’s manager, said, “As a fairly new manager in the Contractor Assurance organization, Kimbel has been a quick study of the complex processes and tools we use. With her outstanding contacts across the nuclear enterprise, she reaches out on a regular basis to benchmark other organizations as well as offer benchmark-quality ideas emanating from our two plants.”

Leffew and Chuck Ramsey (Oak Ridge National Laboratory) accepted the award on behalf of their team. The team was recognized for exceptional performance by a group who was instrumental in addressing a key EFCOG issue. The HPI Working Group turned around its team and provided members products that add value, such as a template for building an HPI strategic plan, an HPI business plan, and HPI assessment tools.

This award also recognizes the team’s contributions to the design and implementation of the HPI curriculum with the creation of the HPI Fundamentals and HPI Lead Practitioner Training Courses under the Performance and Reliability Program in DOE.

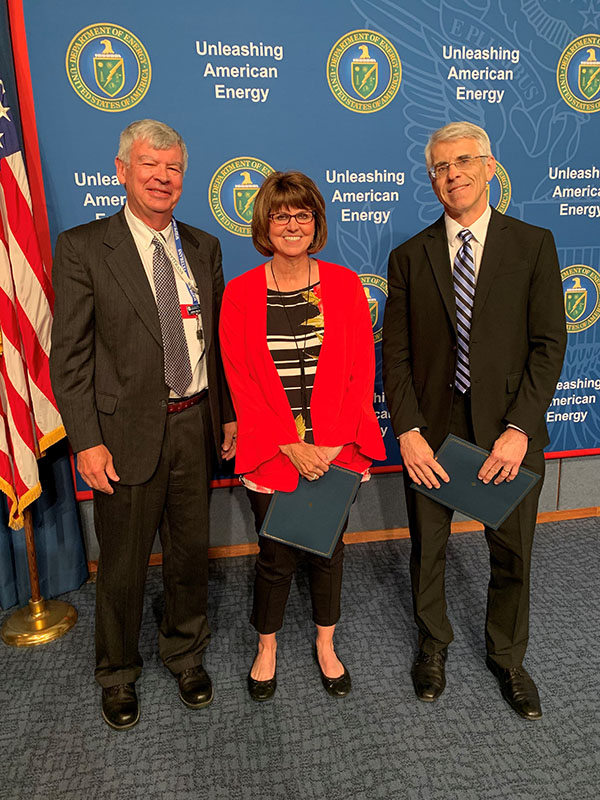

Kimbel Leffew, Pantex Contractor Assurance, and Chuck Ramsey, ORNL, accept the Human Performance Improvement Team Award from the EFCOG Safety Chair John McDonald. Team members not pictured include: Patricia Allen (Savannah River Remediation), Mike Petrowski (Los Alamos National Laboratory), and Lloyd Keith (Washington River Protection Solution).

10 Ways We Strive for Safety at Pantex

1. Protect your health

- Get checked out! An annual physical is a Cigna CNS benefit.

- Know your numbers: blood pressure, cholesterol levels, blood sugar, and body mass index.

2. Insist on Pre-Job Briefings

- Identify scope to be performed and how it will be done; discuss location and potential hazards; know what personal protective equipment is required.

- Know what to do if abnormal conditions occur.

3. Perform the DRIVER steps before operating a vehicle

- Do a 360-degree walk-around; Rely on a spotter; Identify the safety features; Verify safe conditions; Eliminate distractions; Report all accidents.

- Ask your supervisor or safety representative if you have questions

4. Set High Standards to avoid falls in the workplace

- Use ladders properly, including keeping three points of contact when climbing, not leaning to one side when on the ladder, setting the ladder at the proper angle, securing the ladder, etc.

- Ensure use of a proper fall arrest system such as full body harness, self-retracting lanyard, and approved anchor point with 100% tie-off.

5. Be Aware of Hazards in the workplace

- As you begin work, ask yourself:

- Do I have the right tools/equipment for the job?

- Have I inspected my tools/equipment to make sure they are in good repair?

- Am I positioning the tool correctly? Are hands and other body parts out of the line of fire?

- Do I need additional Personal Protective Equipment for the job?

6. Practice Hand Safety

- Our hands are one of our most valuable tools, so protect them.

- Evaluate your work area for potential hand hazards.

- Use the proper tool for the task.

- Wear the right glove for the task.

7. Commute Safely

- Driving to and from work is one of the most dangerous activities we do each day.

- Start SMART

- Secure your seat belt and adjust your seat.

- Make adjustments (check mirrors and eliminate blind spots) before putting vehicle in drive.

- Avoid driving drowsy by getting plenty of rest each night. Lack of sleep causes you to react more slowly, and impairs judgement and vision.

- Remain focused on driving.

- Thoroughly check your surroundings for traffic, people, blind spots, and objects.

- Stay SMART

- Control your Speed.

- Monitor for excessive speed and road conditions.

- Avoid distractions. Follow CNS’s Cellular Telephone/Mobile Electronic Device policy to minimize risk during driving.

- Follow the Rules of the road.

- Take Time to reach your destination. Plan ahead. Allow for extra time.

8. Walking is Working

- Keep these facts in mind when you consider talking or texting while walking:

- Texting decreases your situational awareness and limits eyes on path.

- Five seconds is the average time your eyes are not focused on the path if you are walking while texting.

- Tripping hazards could be one step ahead.

- Own the outcome, stop and take time out to talk or text.

9. Think Before You Act

- Report it, don’t ignore it – report near misses and if something doesn’t’ seem safe report it immediately.

- Always look for hidden hazards – be aware of changes around you and pay attention to detail and the task at hand.

- Keep your mind on the task – remind yourself why certain safety policies and best practices are in place and stop to think before you act – keep a safety mindset!

10. Manage Stress

- Focus on the one thing that’s always within your control: you.

- These steps will help you manage job stress:

- Take responsibility for improving your physical and emotional well-being.

- Avoid pitfalls by identifying knee-jerk habits and negative attitudes that add to the stress you experience at work.

- Learn better communication skills to improve your relationships with managers and coworkers.