Pantex Blog

Integrating Safeguards, Security, & Emergency Services at CNS

Integrating organizations across two states (and two time zones) can be complex. The divisions within the Safeguards, Security, & Emergency Services organization have been working to integrate, standardize and consolidate their many processes at the Pantex Plant and Y‑12 National Security Complex and are making great progress.

Linda Pyatt, Y-12 S&S Performance Assurance Issues Management, assists Gannon Tucker, the CNS SS&ES change control administrator based at Pantex, with consolidating security's document control.

The initial approach was to simply enable department‑level managers to integrate their processes with their counterparts. They were able to identify many ways to integrate, but it became difficult to fully execute those ideas. An Integration Management Team was created and charged with facilitating the divisions through this complex process. The team took on a systems approach and assisted each department manager with developing an integration plan for his or her group then guided and assisted them in surmounting obstacles as they worked through their plans.

Brian Deorocki of SS&ES Operations Management at Pantex explained, “Individual department managers focus on their areas and are not always able to see the big picture as it relates to all of the internal and external connections. The team, however, is able to see the system as a whole and is better able to integrate the moving pieces, so to speak.”

A steering committee oversees integration efforts and resolves issues that could not be resolved at the department level. The committee is comprised of the four direct reports to the SS&ES vice president. Ultimately, the S&S steering committee approves all integrating actions. The Integration Management Team works closely with various teams from Booz Allen Hamilton and is accountable to the steering committee to ensure no independent effort exists that will conflict with the CNS five absolutes.

These positive working relationships have enabled the development of integration plans and consistent processes. For example, the administration of random drug and alcohol testing can now take place at either site for visiting personnel. Also, the Annual Security Refresher Briefing had been a requirement for all personnel at Y-12 when the DOE order only required it for cleared personnel; that process is now standardized at both CNS sites and complies with the DOE order. Weekly security shares, used as security reminders during meetings, are now used jointly at both sites and can be accessed on the CNS intranet. In many cases, just the formalization and documentation of some long‑established informal processes naturally fit into the integration effort. The SS&ES integration strategy has been to work with each program separately and simultaneously.

Performance Assurance is leading the way toward integrating both security programs. This department provides internal services to divisions and easily transcends across those division lines, with standardized processes for assessments, issues management and performance testing. Performance assurance activities can also effectively identify gaps in other integration efforts warranting attention. To date, Performance Assurance is operating as one team to fully integrate the program across the enterprise.

SS&ES teams continue integrating the Pantex and Y-12 programs. A strong foundation cannot occur over night, but CNS security personnel are striving to see it completed soon.

Ken Freeman, SS&ES vice president, said, “The integration effort has been challenging, but we are very pleased with the work our employees are accomplishing. Through their continued collaborative and cooperative efforts, we anticipate having even greater success in FY 2016.”

Pantex supports March of Dimes

Pantex was a proud presenting sponsor of the recent March of Dimes Golf Tournament that took place Aug. 22. CNS contributed $8,000 to benefit the goal of healthy babies and mothers in the area. The annual golf tournament is a popular event among Pantexans. “Not only were we able to have a good time, we were able to support a great cause,” said Todd Ailes, Pantex deputy site manager.

Kenny Steward, Pantex quality operations director, knows the significance of being able to give and how it drives Pantexans to participate in multiple events throughout the year. “As one of the largest employers in the Amarillo area, it is important for us to give back to our community and support many of our charities both local and national,” Steward said. “It was an honor to be one of the 60+ employees to represent CNS and the Pantex Plant at the March of Dimes Golf Tournament.” Steward added that being a part of the first‑place team for the third flight was a nice way to top off the event. Pantexans who participated signed a commemorative banner and received a complimentary golf towel courtesy of CNS.

| Notable team results with Pantex participants | ||

| 1st Flight | 2nd Flight | 3rd Flight |

|---|---|---|

| 2nd Place Mike Smith Corey Boyd Bob McWaters Rick Allford |

3rd Place Paul Diaz Sr. Paul Diaz Jr. Steven Diaz Cameron Diaz |

1st Place Joe Marshall Todd Ailes Bob Asbury Kenny Steward |

| 3rd Place Doug Cruz Curt Hinz Jerry Tenorio Frank George |

2nd Place Jimmy Ramirez Harry West Tim Alvarado Arnold Galbraith |

|

| 6th Place Danny Sena Pat Sena Roger Williams Gary Haynie |

5th Place Tyson Sherwood Detrik Sherwood Grant Singleton Brad Henston |

|

| Long Drive # 18 A.M. — David Vasquez | ||

SBA recognizes Pantex as a leader

The Pantex Plant’s Supply Chain Management organization recently received three awards from the Small Business Administration.

Pantex received the following awards:

- SBA leader in the Lubbock-West Texas District and the SBA Region VI (comprised of Texas, New Mexico, Oklahoma, Arkansas and Louisiana),

- Provider of outstanding stellar access to procurement opportunities for small businesses and

- SBA Procurement All Star.

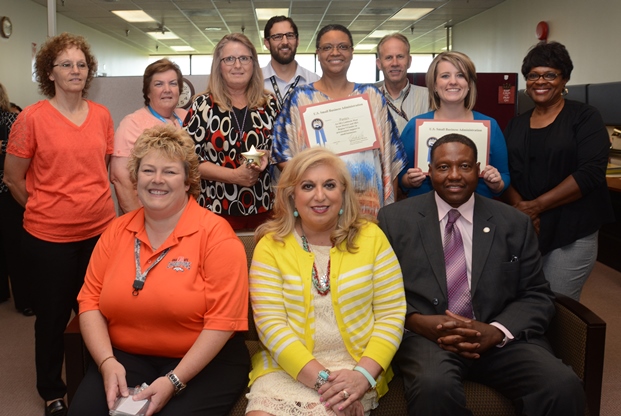

The awards were presented by SBA Region VI District Director Calvin Davis and Regional Administrator Yolanda Garcia Olivarez.

Pantex has a long history of working with small business. Kelly Delgado-Goudschaal, acting manager of Supply Chain Management said, “These awards are a direct reflection of the dedication and the commitment of the Procurement personnel at Pantex. We have had a long-standing tradition of supporting small businesses within our community. We also work with the West Texas Procurement Center to develop and mentor small businesses within our community.”

Achieving the subcontracting goal is part of the plan. “We have an established goal each year as to the amount of dollars to be awarded to small businesses, and we work with a variety of organizations, such as those with expertise in special tooling, packaging and fuels,” according to Compliance team lead Barbara Smith. Consolidated Nuclear Security, LLC has a small business subcontracting goal of 65 percent for the plant.

Smith added, “It is an honor to be recognized by SBA as a leader for promoting small businesses. For the past seven years, we have consistently exceeded our small business goal. Pantexans continue to support SBA initiatives by identifying small businesses with which we can contract.”

Small Business Administration Region VI SBA District Director Calvin Davis and Regional Administrator Yolanda Garcia Olivarez recently presented awards to Pantex’s Supply Chain Management organization. Featured in photo, front row, from left, Kelly Delgado-Goudschaal, Olivarez and Davis. Back row from left, Frances Tillery, Barbara Smith, Teresa Albus, Jeff Gillmore, Tammi Pedro, Randy Lucas, Ashley Hayton and Diane Johnson.

CNS and Metal Trades Council reach new labor agreement

Consolidated Nuclear Security (CNS) was informed by the Metal Trades Council (MTC) that a new four-year labor agreement has been ratified for work at the Pantex Plant. CNS is appreciative that the negotiations and work stoppage are resolved, and Pantex looks forward to all employees represented by MTC returning to work on October 5, 2015.

Reminders for employees returning to work October 5:

- Pantex managers and supervisors will be contacting employees represented by the MTC with instructions on where to report.

- The Pantex Plant is open for normal operations. All personnel are to report for duty according to their regularly assigned schedules.

- Continue to exercise caution as you approach the Plant and slow down to prevent accidents or injuries.

- Safety and security remain top priority. All security and medical reporting requirements remain in place. Also, please remember not to bring Personal Electronic Devices into prohibited areas.

CNS supports women in STEM luncheon

Since the 1940s when they traded in their aprons for coveralls and gas masks, women have played a key role at the Pantex Plant. To honor their past contributions and celebrate the work they currently perform, Consolidated Nuclear Security, LLC was a corporate sponsor of the recent 2015 Louise Daniel Women’s History Luncheon and Women’s Equality Day Celebration.

The sponsorship was fitting because this year’s event highlighted the work done by women in science, technology, engineering and math (STEM) fields.

Natalie Waters, a Pantex industrial engineer, spoke about the history of local women in STEM and presented a vignette about female STEM professionals at Pantex.

“Young girls and women who live in the Panhandle today should be proud of the women pioneers who worked hard, paved the way and excelled in their STEM fields,” said Waters.

The annual event is named for Louise Daniel, a local science teacher and civic volunteer. Before her death in 2003, Daniel requested that her friends create an event to remind women of all ages about women’s historic struggles to achieve equality.

Six years ago, her friends honored this last wish by creating a women’s history lecture fund at the Amarillo College Foundation. They host a lecture and luncheon in August to coincide with Women’s Equality Day, focusing on a different facet of women’s history each year.

Pantex industrial engineer Natalie Waters, Ph.D., was a keynote speaker at the Louise Daniel Women’s History Luncheon. Pantex scientists and engineers attending the event included (from left) Rachel Ehler, Hannah Pemberton, Isela Galan, Erin Robinson, Raquel Barrera-Chavez, Halianne Crawford, Waters, Brandy Ramirez, Meagan Brown, Courtney Waddell, Karishma Myers, Jessie Phifer, Zelda Martinez and Ava Azores.