Pantex Blog

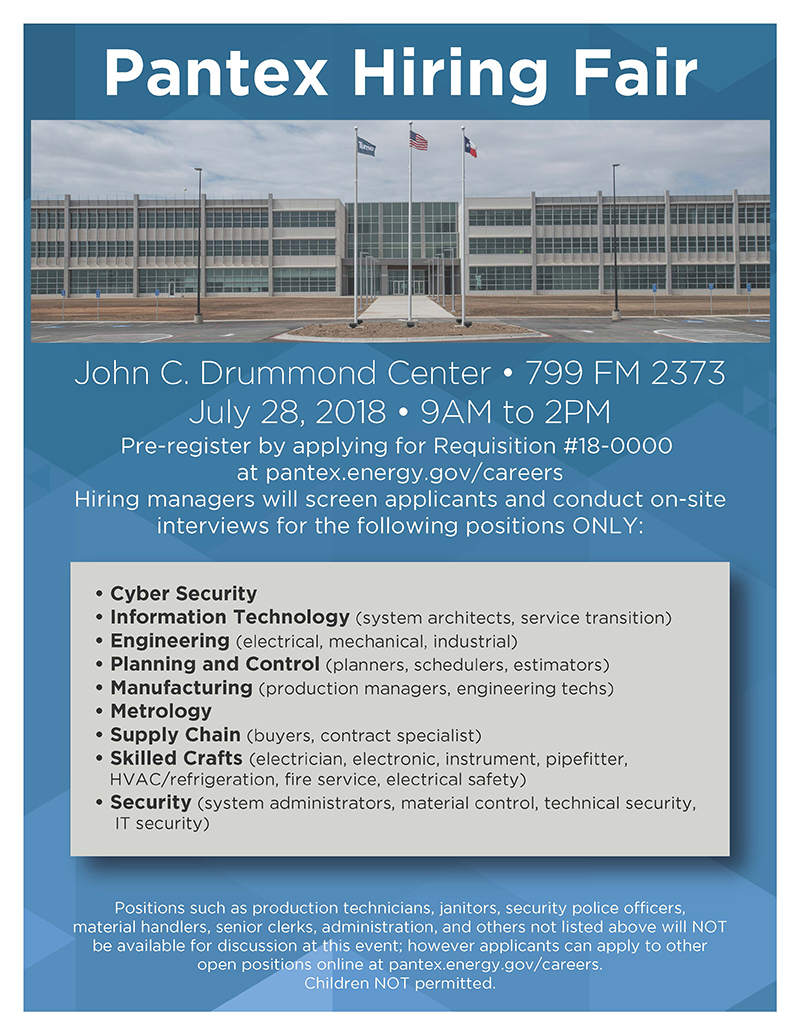

Pantex to hold external hiring event

Pantex is holding a targeted external hiring event on Saturday, July 28 from 9 a.m. to 2 p.m. at the JCDC. Applicants are encouraged to pre-register by applying for requisition 18-0000 on pantex.energy.gov/careers. Submit a resume and identify specialty for the following groups ONLY:

- Cyber security

- Information technology (system architects, service transition)

- Engineering (electrical, mechanical, industrial, engineering techs)

- Planning and control (planners, schedulers, estimators)

- Manufacturing (production managers)

- Metrology

- Supply chain (buyers, contract specialist)

- Skilled crafts: electrician, electronic, instrument, pipefitter, HVAC/refrigeration, fire service, electrical safety

- Security (system administrators, material control, technical security, IT security)

This event is NOT for production technicians, janitors, security police officers, clerks, yard workers, or material handlers. Children not permitted.

25 years of striving for excellence

For the last 25 years, a group of Pantexans have met during lunch to improve their communication and leadership skills. The Pantex Lunch Bunch Toastmasters Club recently celebrated the club’s silver anniversary with a special meeting.

“The Lunch Bunch is one of 15 clubs in the Amarillo area and one of 16,400 clubs around the world, “ said Pantexan Natalie Waters, Toastmasters immediate past District 23 director. “In the past decade, members of club number 9440 have received approximately 111 Toastmasters awards and the club has been designated as Distinguished in eight of the past 10 years.”

Waters, whose term ends June 30, recognized visiting Toastmasters dignitaries and shared the organization’s background and values for visitors and potential members during the event.

Dennis Williams, a Pantex laboratory technician and founding club member, shared how membership has impacted his career, and guest speaker Alonzo Everhart, a Pantex senior operations advisor, shared his tips for communicating in stressful situations. NPO Facility Representative Jessie Phifer acknowledged how far she’s come since her first speech full of fidgeting and filler words.

“I may not have been the ‘um’ queen, but I was the queen of other things such as ‘like’ and ‘you know’,” admitted Phifer.

Keynote speaker Deputy Site Manager Corey Strickland stressed the importance of building a solid communication pipeline and how active listening has helped in his nearly 25-year career at Pantex.

“Effective communication is the cornerstone of being a good leader,” said Strickland.

The 25th anniversary celebration also included door prizes, a club president “changing of the guard”, and a reception for members and guests.

The Pantex Lunch Bunch Toastmasters Club meets Thursdays in the JCDC S1.C102 conference room from 11:30 a.m. to 12:30 p.m. Guests are always welcome.

Safety engineers translate kickball passion to the office

Going by the name “Just Kickin’ It,” a group of employees in Pantex Safety Analysis Engineering (SAE) displayed the true definition of teamwork during last season’s kickball league. The league, organized by @Socialete Sports, gave the SAE team the opportunity to kick balls, run bases, and socialize with people from all walks of life.

The passion on the field translated to the office. “Safety analysts take their work seriously, and we consistently work as a team to get tasks done. Constantly in competition, we work hard against ourselves, peers, and deadlines to meet daily, weekly, monthly, and yearly goals,” team member Terrence Cooper said.

Emergency Management program recognized for strong local partnerships

Pantex Emergency Management received the Texas Emergency Management Partnership Recognition Award at the annual Texas Department of Emergency Management Conference in San Antonio. Each year, this award is given to one business, nonprofit, school, hospital, or government agency for contribution to its local community by demonstrating a significant commitment to creating a strong partnership with the local government officials and participation in local community preparedness initiatives.

Pantex FD Chief recognized

Congratulations to Pantex Fire Chief Mike Brock who has successfully completed the professional designation of chief fire officer.

Manager of Pantex Emergency Services Daniel Gleaves said, “Mike is one of only 1,305 CFOs worldwide. It’s another example of his dedication and professionalism.”

A comprehensive peer review determined Brock met the stringent criteria, which includes demonstrating excellence in his experience, education, professional development, professional contributions, association membership, community involvement, and technical competence.